Kegiatan Edubisnis Training Center - EduBisnis.com

Pendidikan dan Pelatihan Bisnis | Digital Marketing | Kewirausahaan | Manajemen Strategis | Konsultan Pemasaran | Mentoring dan Coaching Secara Khusus beberapa kegiatan yang dilakukan meliputi pelatihan motivasi bisnis, Pelatihan digital marketing, Pelatihan Kewirausahaan, Pelatihan Ketrampilan Usaha, Ketrampilan Public Speaking, Pelatihan Content Marketing

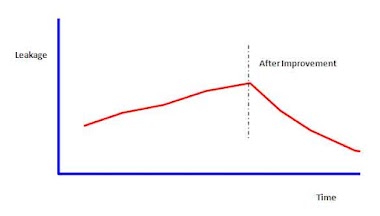

Menampilkan postingan dengan label process improvementTunjukkan semua

Contact Info

Untuk Keterangan Lebih Lanjut Silakan Hubungi Kontak berikut

Contact List

WhatsApp: +62 813-3201-6161

WhatsApp: +62 813-3523-9063

sitemaps